How do solar pool lights resist aging and yellowing from sun exposure, chlorine, and humidity?

Release Time : 2026-01-09

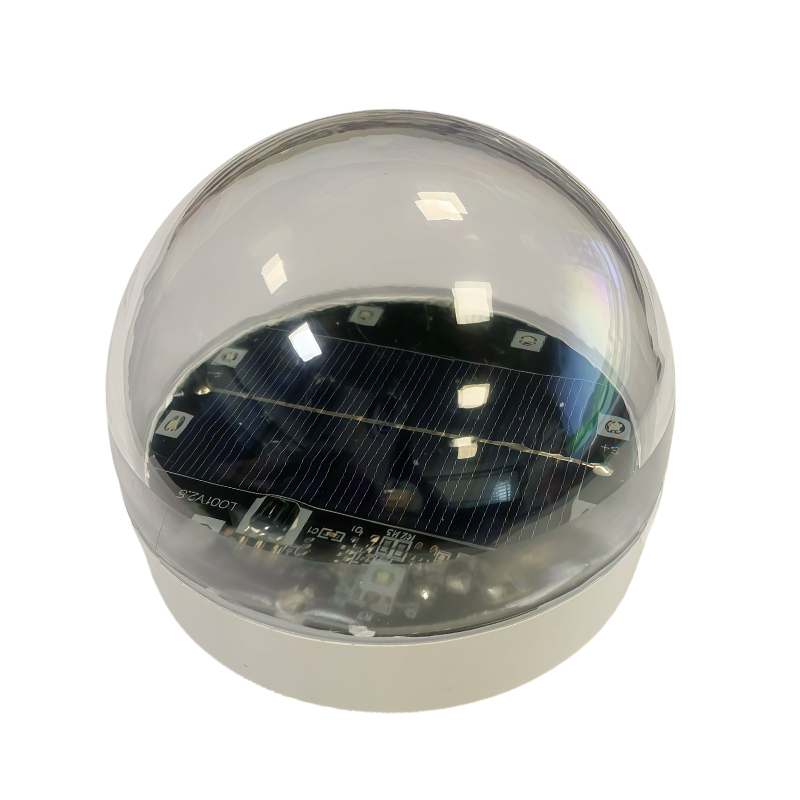

In outdoor landscape lighting, solar pool lights are constantly exposed to the harshest natural environments: scorching summer sun, corrosive chlorine disinfectants in pool water, high humidity at night, and even prolonged underwater immersion. Ordinary plastic products often quickly become brittle, fade, yellow, and even crack under such conditions, affecting not only aesthetics but also potentially jeopardizing the safety of internal electronic components. However, high-quality solar pool lights, specifically designed for water features and gardens, maintain their brightness and vibrant color year after year. Their secret lies in the dual protection of UV-resistant materials and a corrosion-resistant structure.

Firstly, the choice of the solar pool light's casing material is the first line of defense against aging. High-quality solar pool lights use high-grade engineering plastics or special polymers as the main body. These materials have been treated with highly efficient UV absorbers and antioxidant stabilizers during the manufacturing process. When high-energy ultraviolet rays from sunlight hit the surface of the lamp body, these additives actively "capture" and neutralize harmful rays, preventing damage to the polymer chain structure. Therefore, even with prolonged use in tropical regions or high-altitude areas under strong sunlight, the lamp housing will not yellow, powder, or lose its luster due to photo-oxidation, maintaining a clear, transparent, or pure colored appearance to ensure unobstructed light output.

Secondly, addressing the chemical corrosion challenges of swimming pools and fountains, the structural design and material formulation work together. Pool water commonly contains strong oxidizing disinfectants such as hypochlorite, which are significantly corrosive to metals and ordinary plastics. Therefore, easily corroded metal parts are avoided in key areas of the lamp body, instead employing a one-piece all-plastic structure or chlorine-resistant alloys; the sealing rings are made of inert materials such as fluororubber or silicone, which are both hydrolytically and chemically resistant. Simultaneously, the entire lamp fixture achieves a seamless seal through precision injection molding and ultrasonic welding, combined with an IP68-level fully sealed design, effectively preventing chlorine-containing water vapor from penetrating the interior and protecting the circuitry and battery from corrosion.

A deeper level of protection is reflected in the details and surface finish. The lampshade is typically made of high-transmittance polycarbonate (PC) or modified acrylic material with a built-in UV-resistant coating. This not only ensures uniform light transmission but also resists scale buildup and algae growth. Even in prolonged humid environments, the surface is less prone to fogging or white spots. The color masterbatches used in the colored lamp bodies undergo weather-resistant treatment to ensure they do not fade or distort under alternating UV radiation and humidity, keeping the red, blue, and green ambient lights vibrant and lifelike.

Firstly, the choice of the solar pool light's casing material is the first line of defense against aging. High-quality solar pool lights use high-grade engineering plastics or special polymers as the main body. These materials have been treated with highly efficient UV absorbers and antioxidant stabilizers during the manufacturing process. When high-energy ultraviolet rays from sunlight hit the surface of the lamp body, these additives actively "capture" and neutralize harmful rays, preventing damage to the polymer chain structure. Therefore, even with prolonged use in tropical regions or high-altitude areas under strong sunlight, the lamp housing will not yellow, powder, or lose its luster due to photo-oxidation, maintaining a clear, transparent, or pure colored appearance to ensure unobstructed light output.

Secondly, addressing the chemical corrosion challenges of swimming pools and fountains, the structural design and material formulation work together. Pool water commonly contains strong oxidizing disinfectants such as hypochlorite, which are significantly corrosive to metals and ordinary plastics. Therefore, easily corroded metal parts are avoided in key areas of the lamp body, instead employing a one-piece all-plastic structure or chlorine-resistant alloys; the sealing rings are made of inert materials such as fluororubber or silicone, which are both hydrolytically and chemically resistant. Simultaneously, the entire lamp fixture achieves a seamless seal through precision injection molding and ultrasonic welding, combined with an IP68-level fully sealed design, effectively preventing chlorine-containing water vapor from penetrating the interior and protecting the circuitry and battery from corrosion.

A deeper level of protection is reflected in the details and surface finish. The lampshade is typically made of high-transmittance polycarbonate (PC) or modified acrylic material with a built-in UV-resistant coating. This not only ensures uniform light transmission but also resists scale buildup and algae growth. Even in prolonged humid environments, the surface is less prone to fogging or white spots. The color masterbatches used in the colored lamp bodies undergo weather-resistant treatment to ensure they do not fade or distort under alternating UV radiation and humidity, keeping the red, blue, and green ambient lights vibrant and lifelike.

Furthermore, low maintenance requirements are a direct result of this durable design. Users do not need to regularly wipe, replace, or apply protective coatings; solar pool lights can silently operate underwater or on the shore, maintaining their appearance year-round. This "install and forget" characteristic greatly enhances the user experience, making it particularly suitable for villa courtyards, resorts, and other settings that prioritize long-lasting aesthetics and low maintenance costs.

Ultimately, the reason why solar pool lights can withstand exposure to sunlight, chlorine, and moisture without aging or yellowing is not due to the sheer brute force of a single material, but rather the result of a systematic engineering achievement, from molecular-level UV-resistant formulations and chemically inert materials to a fully sealed structural design. It conceals technology behind the light and shadow, silently and resiliently protecting the brilliance of each night. When dawn breaks and the lights go out, their outer shell remains as bright as ever—this is the gentlest interpretation of "standing the test of time."